High Precision Double row angular contact ball bearings

Ultra high speed, high stiffness, high carrying capacity, good running performance, easy mounting of universally matchable bearings, suitable for oil and gas lubrication or injection lubrication.

Product Description

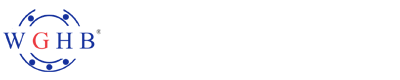

Single row rowangular contact ball bearings

Double rowangular contact ball bearings

Angular contact ball bearings have raceways on the inner and outer rings, and the inner and outer rings can be displaced relative to each other along the axial direction of the bearing. These bearings are particularly suitable for withstanding composite loads, ie loads acting simultaneously in both radial and axial directions. The axial load bearing capacity of the angular contact ball bearing increases as the contact angle α increases. The contact angle is the angle between the line connecting the contact point of the ball and the raceway in the radial plane and the vertical line of the bearing axis.

Angular contact ball bearing accuracy class includes dimensional tolerance and rotation accuracy. From low to high accuracy is expressed as P0(ordinary), P6(P6X), P5, P4, P2, in addition, P3, P7, P9 are also used in European and American brands to indicate accuracy levels, P3 is equivalent to level P6 of ISO and JS standards, P7 is equivalent to level P4, and P9 is equivalent to level P2.

The characteristic of angular contact bearing is that it can bear both radial load and single axial load. The larger the contact Angle, the larger the axial load, the smaller the contact Angle, the smaller the axial load. Conversely, the smaller the contact Angle, the greater the ability to bear radial loads, and the more suitable for high-speed applications. According to different working conditions, it can be combined in a variety of ways to obtain different radial and axial load capacity, and meet the requirements of high speed and diameter, and high axial stiffness.

Product features of angular contact ball bearing:

High-quality bearing materials:

WGHB adopts ultra-clean steel, high purity high-carbon chromium bearing steel GCr15 from a well-known domestic manufacturer, which can extend the life of the bearing by 80%.

High quality bearing rolling elements:

The bearing balls provided by WGHB have good product performance to ensure the optimal bearing configuration and smooth operation at high speed and quiet. WGHB has a complete process production line, from powder ultrasonic pre-dispersion, mixture mixing, spray drying granulation, near-net-size molding, cold isostatic pressing, GPS-HIP combined sintering process, high-precision grinding and processing, total quality inspection to packaging.

More suitable bearing cage:

WGHB mostly adopts bakelite cage, which can more effectively reduce the friction between metal and bearing balls and extend the life of the bearing. WGHB can also choose more suitable bearing cage materials according to customer requirements and bearing applications.

Advanced lubrication technology:

WGHB uses high performance grease and advanced lubrication technology to extend bearing life and improve bearing performance.

Ultra finished raceways:

WGHB uses special honing to minimize noise, improve lubricant dispersion and increase bearing life.

Contact angle:

WGHB ultra high speed precision bearings usually use 15°and 25° contact angles.

Accuracy grade:

WGHB can offer the high precision angular contact ball bearings with P2, P4A, P4 grade.

Jinan Shengbang Bearing Co., Ltd. is a modern precision bearing manufacturer integrating R&D(research and development), production and sales. Our company has advanced production equipment, fully adopting advanced production technology and modern testing equipment to improve the precision performance of our products. The company promotes the"WGHB" brand, specializing in the production of deep groove ball bearings, taper roller bearings, spherical roller bearings, cylindrical roller bearings, pillow block bearings and other special bearings and non-standard bearings.

Our products with high precision and low noise, are widely used in metallurgy, mining,petroleum,chemical,coal, cement, paper,wind power, heavy machinery, port machinery and other industries. The company has independent import and export management rights. The products are sold all over the world, exported to more than fifty countries and regions such as South America,Western Europe, Southeast Asia, Central Asia, Africa and Australia.

The company always takes "solution, creation, value" as business philosophy, providing excellent bearing solutions for domestic and foreign customers. WGHB Bearings has passed ISO9001:2008 and ISO14001:2004. Through the implementation of strict quality standards, taking rigorous quality control measures to improve product quality and service quality, WGHB Bearings provides high quality products and services to consumers around the world.

Welcome all your OEM and ODM order. Your spefic purchase needs of selecting current product from our catalogue or seeking engineering assistance for your application will be directly submit to our customer service center, we will answer you ASAP.

Applications:

WGHB super high speed single row angular contact ball bearings might be used in the fields of machine tools, textiles, automobiles, railways, metallurgy, chemicals, electronics, Industrial pumps, Compressors, Material Handling, Electric motors.